-

Clamps Crane YBFor more details

Clamps Crane YBFor more details -

Four-link Portal CraneFor more details

Four-link Portal CraneFor more details -

Marine Hatch Cover Gantry CraneFor more details

Marine Hatch Cover Gantry CraneFor more details -

Wire RopesFor more details

Wire RopesFor more details

- Product Overview

- Application Scenario

- Certificate

When selecting a multi-function crane for electrolytic aluminum production, every detail matters—from initial quality and brand reputation to long-term reliability and service support. Our Multi-Function Crane is purpose-built to exceed expectations at every stage of your decision-making process, delivering not just equipment, but a seamless partnership from design to delivery and beyond.

Why Our Crane Stands Out—A Client-Focused Advantage Overview

✅ Initial Screening Phase: Trust in Brand and Build Quality

Proven Expertise in Electrolytic Aluminum Applications: Designed specifically for anode baking furnace operations—handling raw anode blocks, filler coke, and baked anodes with precision.

Superior Structural Integrity: Fabricated from high-strength Q355B steel with FEM-optimized design. Built for A8 duty class, ensuring resilience under continuous heavy-duty cycles.

Competitive Pricing Without Compromise: We offer cost-efficient solutions that don’t sacrifice quality—helping you maximize ROI from day one.

✅ Mid-Stage Comparison: Responsive Service & Technical Collaboration

Rapid Design & Quotation Support: Receive customized layout proposals and RFQ responses within 48 hours. Our engineers work closely with you to tailor crane type, trolley configuration, and operational parameters to your facility.

Efficient, Expert Consultation: Get clear, professional guidance on technical specs—from vacuum extraction rates (up to 65 t/h) to dust emission control (≤10 mg/m³). We help you optimize performance while adhering to environmental standards.

Transparent Communication: Timely updates, detailed drawings, and flexible design adjustments ensure you’re confident before committing.

✅ Final Decision Phase: Reliable Post-Purchase Assurance

Comprehensive After-Sales Service: Warranty coverage, readily available spare parts, and dedicated technical support—minimizing downtime and extending crane lifespan.

Flexible Payment & Inspection Options: We support various payment terms and welcome pre-delivery factory inspections. Watch your crane being built—track progress and verify quality firsthand.

Long-Term Performance Guarantee: From robust cooling and dust removal systems to smooth PLC-controlled automation, our cranes are built to perform year after year, reducing maintenance costs and boosting productivity.

Key Technical Highlights

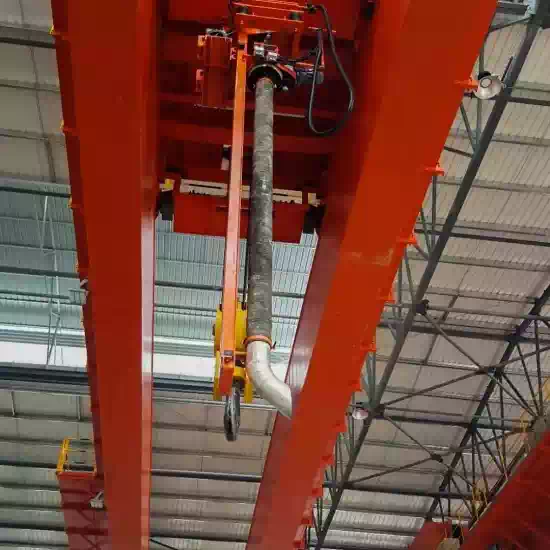

Multi-Functional Tool Trolley: Handles anode clamping, coke filling, vacuum extraction, and auxiliary lifting—all in one integrated system.

Eco-Conscious Operation: Closed-loop material recycling and multi-stage filtration ensure dust-free, environmentally compliant performance.

Smart Automation Ready: Upgradeable to semi- or fully automated operation with PLC and variable frequency drives for precise control and energy savings.

Adaptable Design Configurations: Choose between modular or trolley layouts to maximize space and minimize wheel load—cutting structural costs for your workshop.

Industries Served

Aluminum Smelting

Carbon Anode Production

Metallurgical & Mining Plants

Choose a partner who understands your workflow, your budget, and your long-term goals.

Let’s discuss your project needs—request a detailed proposal, design layout, or factory visit today.

Beyond reliable service and partnership, the fundamental value of our Multi-Function Crane lies in its precision engineering and innovative features designed explicitly for the harsh environment of anode baking furnaces.

1. Unmatched Process-Specific Adaptability

Intelligent Anode Clamping System: Engineered with a pressure-compensating clamp mechanism that securely handles fragile carbon blocks without causing cracks or damage. Configurable for 2x6t or custom block quantities.

High-Temperature Vacuum Conveying: Features a reinforced, heat-resistant pipeline and suction system capable of handling filler coke at sustained temperatures of ~450°C (peaks of 600°C), ensuring continuous operation without downtime.

Dedicated Dust Control & Cooling: An integrated multi-stage purification system (cyclone + bag filter) actively cools and captures dust during extraction, maintaining workshop air quality and guaranteeing emissions consistently below 10mg/m³.

2. Engineered for Maximum Uptime & Structural Longevity

Heavy-Duty A8 Classification: Unlike standard cranes (A3-A5), our design is built for intensive, 24/7 cyclic operation typical in electrolytic aluminum production, translating to a longer operational lifespan and lower cost-per-year.

Robust Girder & Travel System: The bridge girder, constructed from high-grade Q355B steel, utilizes a FEM-optimized structure for superior strength-to-weight ratio. The 3-in-1 geared travel motors and high-load wheels minimize wear on runways and reduce long-term maintenance.

3. Operational Intelligence & Smooth Control

PLC-Based Control System: The heart of the crane allows for precise, repeatable movements, programmable logic for complex sequences, and seamless integration with plant-wide automation systems for a smart factory setup.

Variable Frequency Drives (VFDs) on All Motions: Ensure smooth acceleration and deceleration in hoisting, traveling, and trolley movements. This eliminates load swing, protects delicate anodes from impact, and significantly reduces mechanical stress on the entire structure.

4. Modular & Maintenance-Friendly Design

Pre-Engineered Modular Subsystems: Key components like the tool trolley, electrical panels, and drive units are designed as modular blocks. This allows for faster installation, easier troubleshooting, and dramatically reduced maintenance time.

Easy Access for Servicing: Strategic access points and hatches are incorporated into the design, enabling quick inspection and replacement of critical parts like filters, electrical components, and wearing pads, minimizing operational disruption.

5. Customization to Fit Your Exact Layout

Flexible Trolley Configurations: We offer both standard and下沉式 (lowered girder) trolley designs to maximize your hook height and optimize space within low-clearance workshops.

Optimized Wheel Load Distribution: The optional 4-wheel per side travel system spreads the load more evenly, which can lead to substantial savings on your building's supporting steel structure costs.

In essence, we don't just sell a crane; we provide a fully integrated, high-performance material handling solution. It's built to withstand the abrasive, high-heat, and dusty conditions of your facility while ensuring precision, efficiency, and unparalleled reliability.