-

Clamps Crane YBFor more details

Clamps Crane YBFor more details -

Multifunctional Crane for Electrolytic CopperFor more details

Multifunctional Crane for Electrolytic CopperFor more details -

Crane Wireless Remote ControFor more details

Crane Wireless Remote ControFor more details -

Multi-Function Crane for Electrolytic AluminumFor more details

Multi-Function Crane for Electrolytic AluminumFor more details

- Product Overview

- Application Scenario

- Certificate

1. Engineered for Long-Term Reliability & Cost Efficiency

Robust Construction & Premium Components: Built with high-strength, wear-resistant materials to withstand heavy-duty cycles and extreme conditions (e.g., temperatures up to 300°C near furnaces). This minimizes maintenance needs and extends service life, reducing total ownership costs.

Energy & Infrastructure Savings: An integrated frequency conversion system cuts power consumption by 30% and reduces structural stress on your facility. Ideal for retrofitting existing plants without costly reinforcements.

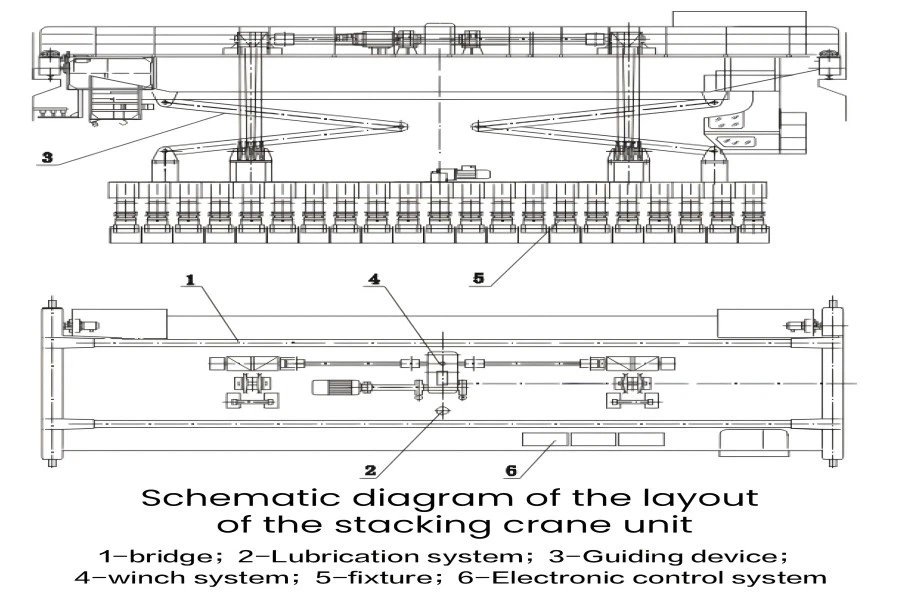

2. Precision Automation for Enhanced Productivity

Intelligent Dual-Spreader System: Ensures precise vertical alignment (±5mm accuracy) and adaptive grip force control, preventing anode slippage even at high temperatures.

Seamless Workflow Integration: Fully automated unloading, stacking, and transfer processes (handling up to 19 blocks per cycle) eliminate manual handling risks and boost output.

3. Proactive Support from Consultation to After-Sales

Expert Guidance & Customization: Receive timely, professional consultations with detailed design drafts and RFQ responses tailored to your facility’s layout and operational needs.

Reliable Post-Purchase Assurance: Comprehensive售后 support includes installation supervision, operator training (<8 hours), and real-time production updates. Flexible payment terms and factory audit options available.

4. Built for Safety & Harsh Environments

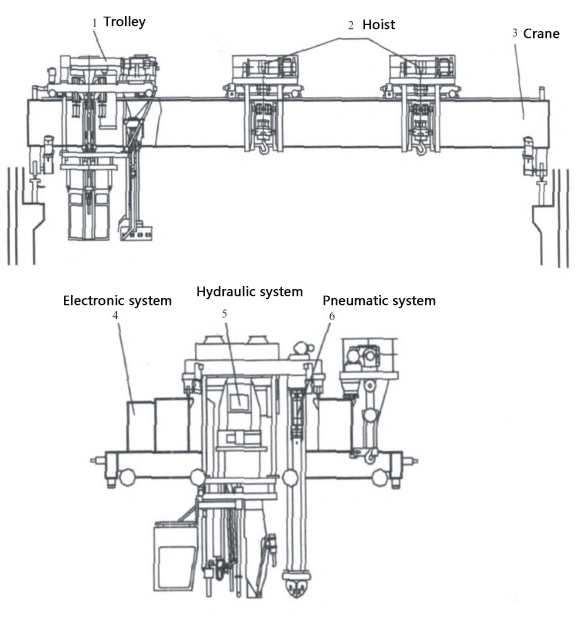

Multi-Layer Protection Systems: Advanced sensors (load, tilt, temperature) and fail-safe mechanisms (emergency brakes, dustproof electrical cabinets) ensure uninterrupted operation in dusty, high-heat workshops.

Risk Mitigation: Automated processes remove workers from hazardous zones, while centralized monitoring simplifies troubleshooting.

Ideal for smelters and carbon baking facilities seeking a future-proof stacking solution that balances upfront affordability with long-term operational savings.

✅ Key Highlights:

Lower construction & energy costs

Precision automation & minimal error rates

24/7 durability in extreme conditions

End-to-end technical & service support