-

General Metallurgy Overhead CraneFor more details

General Metallurgy Overhead CraneFor more details -

Crane Wireless Remote ControFor more details

Crane Wireless Remote ControFor more details -

Container Lifter SpreaderFor more details

Container Lifter SpreaderFor more details -

Rubber Tyred Container Gantry CraneFor more details

Rubber Tyred Container Gantry CraneFor more details

- Product Overview

- Application Scenario

- Certificate

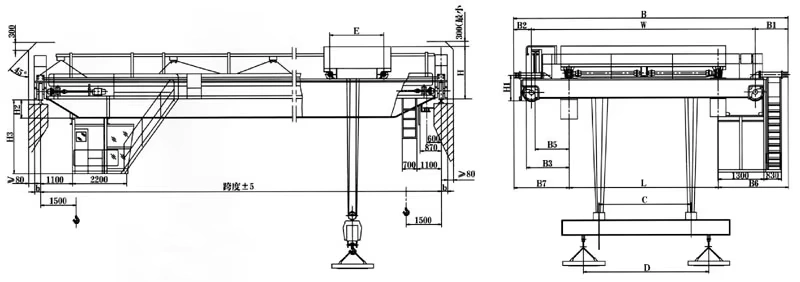

Product Introduction

Our Smart Grab Crane is an advanced, automated handling solution designed specifically for waste-to-energy (WtE) and biomass processing plants. Engineered with cutting-edge automation, precision control, and energy-saving technologies, this crane enhances safety, efficiency, and productivity in waste handling operations.

Key Features & Innovations:

Anti-Sway Control

Advanced PLC programming and real-time communication technology significantly reduce grab swing, improving operational precision and productivity.

Millimeter-Level Positioning

High-precision positioning with automatic correction for wheel slippage, wear, or uneven rails ensures accurate material handling.

Fully Automated Operation

Auto-Feeding: Single-touch commands move the grab to designated hopper positions, optimizing feeding cycles and preventing material bridging.

Auto-Parking: The crane automatically returns to a safe parking position after completing tasks.

Smart Material Collection: Scans and maps waste pile profiles, then systematically collects material from optimal layers.

Energy-Saving Technology

Regenerative braking reduces energy consumption, lowering operational costs.

Intelligent Diagnostics & Safety

Self-Diagnosis: Detects faults (overload, drive errors, electrical issues) and displays error codes for quick maintenance.

Anti-Collision System: Laser/infrared sensors prevent collisions between cranes and with pit boundaries.

Remote Monitoring: Real-time data tracking enables predictive maintenance and performance optimization.

Weighing & Reporting

Integrated weighing system with auto-calibration, overload protection, and customizable reporting (by shift, operator, or date). Data can be exported to central DCS systems.

Ergonomic & Flexible Control

Human-Machine Interface (HMI): Siemens Touch Panel for intuitive operation.

Multi-Mode Operation: Manual, semi-auto, and full-auto modes with optional remote control.

Robust & Reliable Design

Compliant with ISO, FEM, EN, IEC, DIN standards.

High-quality, field-proven components with redundant load capacity for harsh environments.