Product manual

Product manual

- Product Overview

- Application Scenario

- Certificate

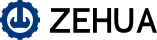

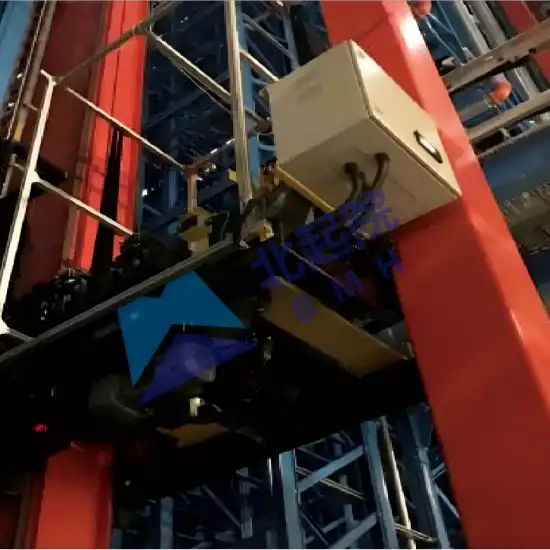

Intelligent Storage Stacker Crane – Efficient, Flexible, and Automated Handling Solution

Product Overview

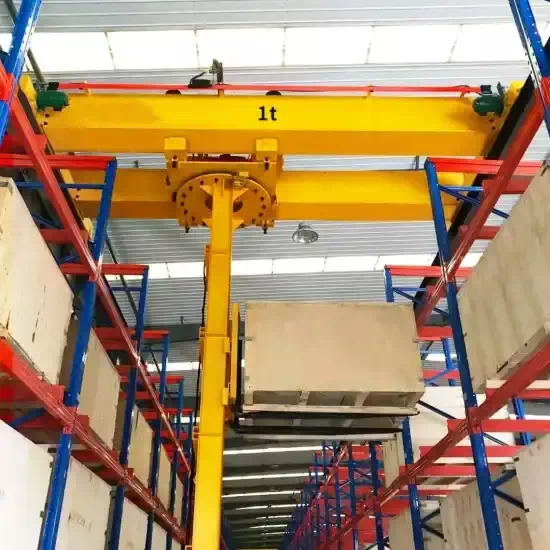

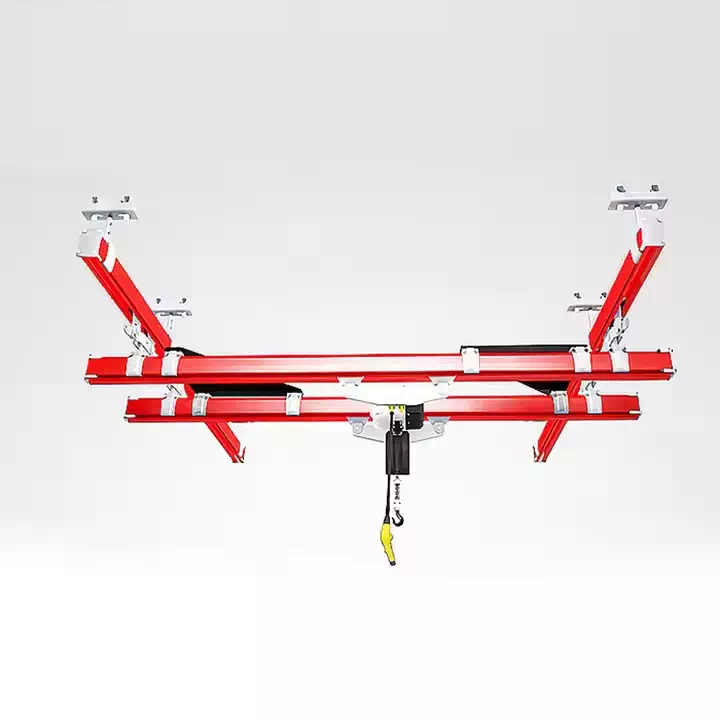

Our Intelligent Storage Stacker Crane is a high-performance handling system designed for modern warehouses and factories. Combining KBK double-beam suspension cranes with specialized stackers, it streamlines storage and material handling operations without the need for ladders, sorting vehicles, or additional equipment. Capable of safely transporting, sorting, and storing loads, boxes, or pallets weighing up to 500 kg, this system enhances efficiency while minimizing manual labor.

Key Features & Advantages

Flexible Handling & Precision Control

Equipped with customizable lifting tools (forks, mandrels, grabbers) to match various load types.

360° rotation for easy maneuvering, ensuring accurate load pickup and placement.

Simple manual operation or advanced semi-automatic/fully automatic control modes for different workflow needs.

High Efficiency & Space Optimization

Fast handling and storage/retrieval speeds, reducing operational downtime.

Compact design allows operation in narrow aisles, maximizing warehouse space utilization.

Suitable for high-rise shelving, ideal for automated storage and retrieval systems (AS/RS).

Advanced Automation & Stability

Remote-controlled operation with minimal manual intervention.

High reliability and stability, even under continuous high-load operation.

Safety & Energy Efficiency

Multiple safety protections: safety door linkage, aisle monitoring, real-time cameras, and safety rope locks.

Energy-saving technology with regenerative braking and anti-push control, reducing power consumption.

Optimized Structure: Lightweight yet durable design using finite element analysis and a rigid-flexible column combination for enhanced strength and space efficiency.

Precision Control: Integrates high-speed anti-sway and millimeter-level positioning for smooth, accurate operations.

Durability & Performance: Engineered for long-term high-load operation, reducing maintenance costs while ensuring reliability.