Product manual

Product manual

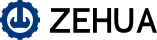

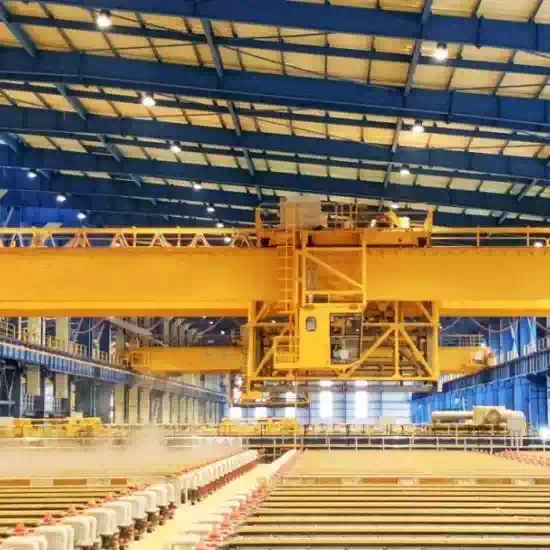

- Product Overview

- Application Scenario

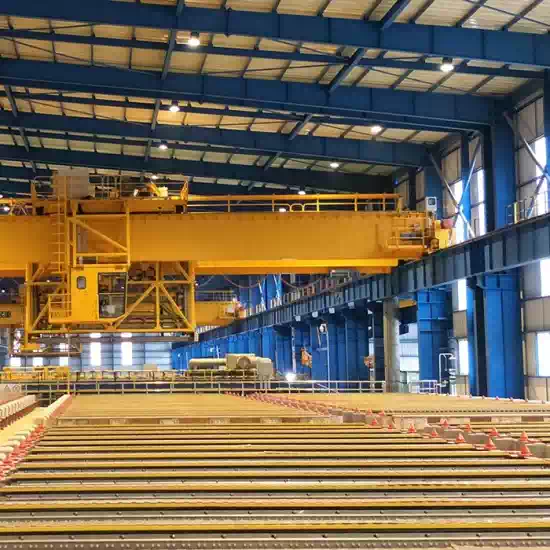

- Certificate

When selecting a crane system for demanding applications like electrolytic copper production, every detail matters—from mechanical strength and intelligent control to long-term reliability and supplier support. Our Multifunctional Crane for Electrolytic Copper is designed not only to meet but exceed these expectations, offering a fully integrated lifting solution tailored to harsh industrial environments.

🔩 Built to Endure – Robust Design & Superior Materials

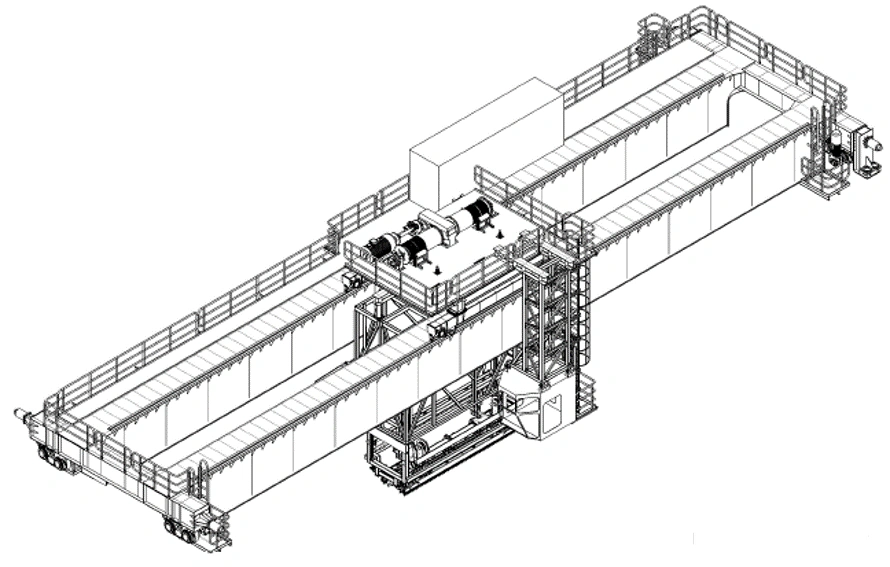

Heavy-Duty Load Capacity (32t) & Customizable Spans (25.5m–31.5m)

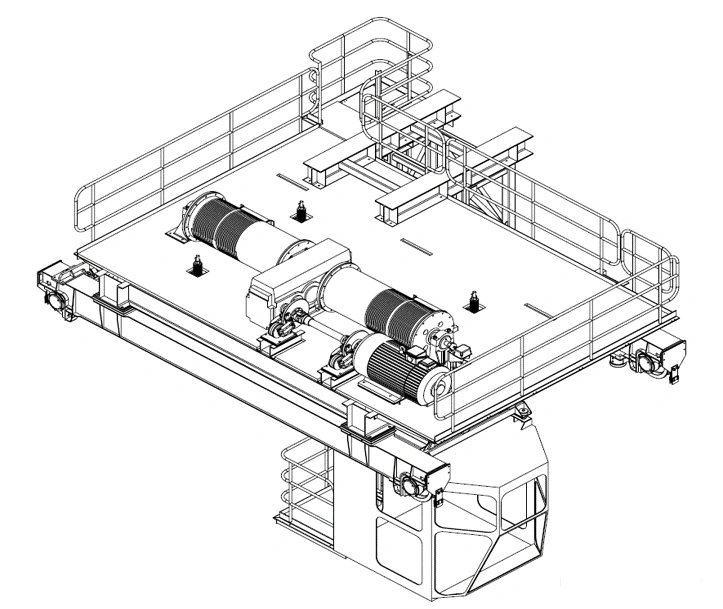

Engineered with a reinforced double-girder structure and high-strength steel, this crane maintains stability and precision under continuous heavy loads. Ideal for lifting, transporting, and stacking electrolytic copper plates with minimal deflection.Corrosion-Resistant Construction

Specialized coatings, sealed electrical components, and stainless-steel critical parts protect against humidity, acidic vapors, and conductive copper dust—extending equipment life even in aggressive environments.Anti-Sway & Precision Positioning

Advanced synchronizing hoists and automatic alignment systems ensure smooth, balanced lifting—preventing plate damage and improving operational safety.

🧠 Smart Control & Automation – Efficiency Meets Intelligence

Seamless Integration into Automated Workflows

Fully compatible with Industry 4.0 standards. Enable remote operation, real-time diagnostics, and IoT-based predictive maintenance to minimize downtime and optimize productivity.Flexible Operation Modes

Choose from cabin, remote, or ground control based on your facility’s workflow. All systems include fail-safe manual override for uninterrupted operation.Customizable Spreader & Tooling

We design and integrate intelligent spreaders tailored to handle electrolytic copper plates securely and efficiently, with options for automated pickup and placement.

⚙️ Engineered for Safety & Compliance

Electrical Insulation & Hazard Protection

Critical insulation between crane and spreader prevents current leakage when operating near electrolytic cells, protecting both personnel and equipment.Global Standards Compliance

Designed in accordance with ISO, FEM, and CE standards, with optional certifications available to meet regional safety regulations.

💡 Your Partner from Start to Finish

We understand that choosing the right crane involves more than just specs—it’s about trust, service, and long-term value.

✅ Initial Consideration Phase

Proven Performance & Brand Reputation

With years of specialization in industrial cranes, our products are trusted by global copper refineries and smelters.Competitive Pricing Without Compromising Quality

We offer transparent cost breakdowns and value-engineered solutions to match your budget.

✅ Evaluation & Quotation Stage

Responsive & Expert Technical Support

Receive layout designs and CAD drawings within 48 hours. Our engineers work closely with you to fine-tune crane specs—span, lift height, control mode, and more.Clear & Detailed RFQ Process

Get a timely, professional quotation with no hidden costs. We help you compare options and customize financing or leasing terms.

✅ Final Decision & Post-Purchase Assurance

Comprehensive After-Sales Service

From installation supervision and operator training to readily available spare parts and 24/7 remote troubleshooting.Production Transparency & On-Time Delivery

Visit our facility or receive regular production updates. We keep you informed every step of the way.Warranty & Lifespan Commitment

Enjoy peace of mind with extended warranty options and a crane built to perform for decades under intense usage.

🏭 Ideal Applications

Electrolytic copper refineries

Copper smelting and casting plants

Mining and heavy material logistics centers

Automated metal processing lines

Choose a crane that works as hard as you do.

Let’s discuss your project requirements—request a customized proposal, design layout, or factory tour today.