Is your material handling process creating bottlenecks, safety risks, or inefficiencies in your production line? The Rotary Feeding Crane isn't just another piece of equipment—it's a targeted solution for the most challenging industrial environments. Discover how it delivers transformative results in your specific application.

Where It Transforms Operations: Real-World Scenarios

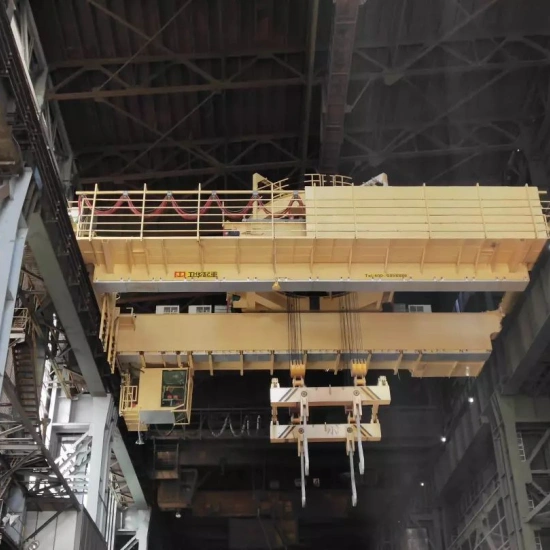

1. Steel Mills: Mastering Scrap Charging & Hot Metal Handling

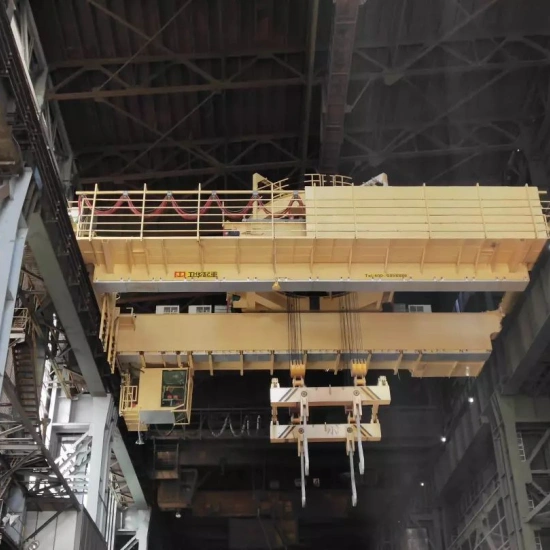

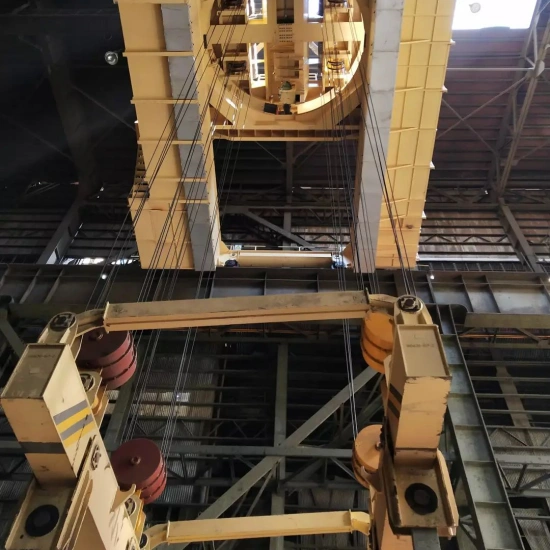

The Daily Challenge: Imagine the tight, hazardous space between your furnace and the workshop wall. A standard crane struggles, requiring multiple maneuvers and incomplete tilts, leaving scrap behind and slowing down your melt shop. The heat is intense, and every second counts.

Our Solution in Action: The Rotary Feeding Crane changes the game. With its full 270-degree rotation, it elegantly navigates the congestion. It approaches the furnace, achieves a high tipping angle (>60°) in a single, fluid motion, and ensures a complete, clean discharge of scrap into the molten bath. This slashes cycle times, boosts your melt efficiency, and keeps operators safer at a greater distance from the intense heat with its fire-resistant construction.

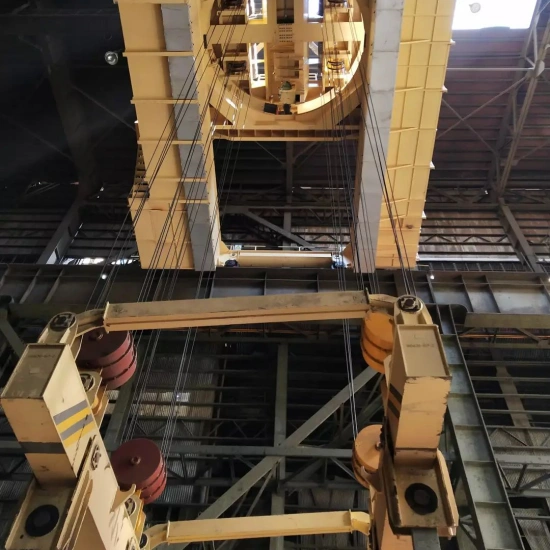

2. Foundries & Smelting Plants: Reliable Hot Metal Loading

The Daily Challenge: Feeding charge materials into a roaring furnace exposes both your equipment and operators to extreme radiant heat and potential spill hazards. Downtime from heat-damaged components is costly and unpredictable.

Our Solution in Action: Engineered for endurance, our crane operates reliably in these punishing conditions. The heat-resistant design of critical components protects against thermal degradation, while stable, precise movements prevent dangerous swaying or spills when handling molten metal containers. This means continuous, reliable operation, reduced maintenance costs, and enhanced foundry productivity.

3. Scrap Yards & Bulk Recycling: High-Volume Material Processing

The Daily Challenge: You're moving massive, irregularly shaped scrap piles or other bulk materials. You need a crane that won't buckle under the load, one that provides the stability to prevent accidents and the power to maintain fast processing cycles.

Our Solution in Action: Built with a high safety factor and robust structure, this crane is a powerhouse of stability. It confidently lifts and transports high-tonnage loads, whether feeding a shredder or organizing a scrap pile. The low-friction, high-precision controls allow operators to handle loads smoothly and efficiently, maximizing throughput and ensuring a safer yard environment.

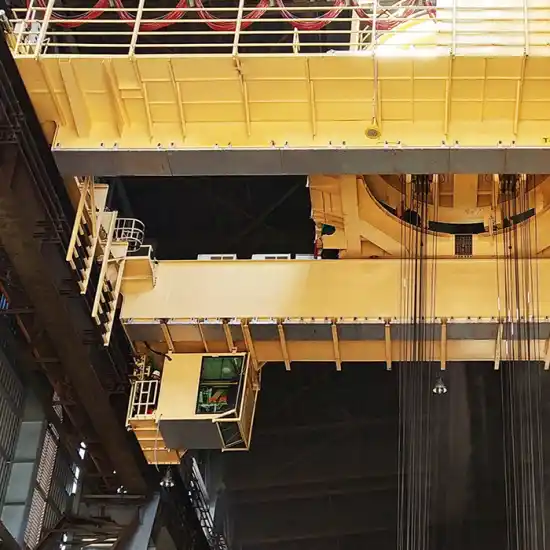

4. Heavy Industrial Plants & Logistics Hubs

The Daily Challenge: In a crowded workshop or storage bay, space is a premium. A bulky, inflexible crane can become an obstacle itself, limiting workflow and layout options.

Our Solution in Action: The compact and highly maneuverable design of the Rotary Feeding Crane makes it the ideal choice for space-optimized facilities. Its ability to rotate and operate effectively in a tight footprint allows you to maximize your valuable floor space without compromising on lifting capacity or operational reach.

Beyond the Scenario: Your Assurance at Every Step

Understanding the application is just the first step. You need a partner who ensures the solution fits perfectly and delivers long-term value.

Do you have a unique layout or a specific material? Our technical team doesn't just sell a standard product. We engage in detailed consultations to understand your site-specific challenges. We provide prompt, professional design drawings and specify the exact parameters your operation requires.

Is the (RFQ) clear and competitive? We believe in transparency. You will receive a detailed, timely, and professional quotation that clearly outlines the value and justifies the investment, helping you make a confident comparison.

Concerned about the build quality and project timeline? We maintain open communication throughout production. We can facilitate factory visits and provide progress updates, so you are never in the dark.

What happens after installation? Our commitment is long-term. From responsive after-sales support and readily available spare parts to comprehensive warranty policies, we ensure your crane remains a reliable asset for years to come, securing your productivity and ROI.

Stop adapting your process to equipment limitations. Let the equipment adapt to you.

[Contact Us for a Free, No-Obligation Site Evaluation and Custom Solution Proposal!]

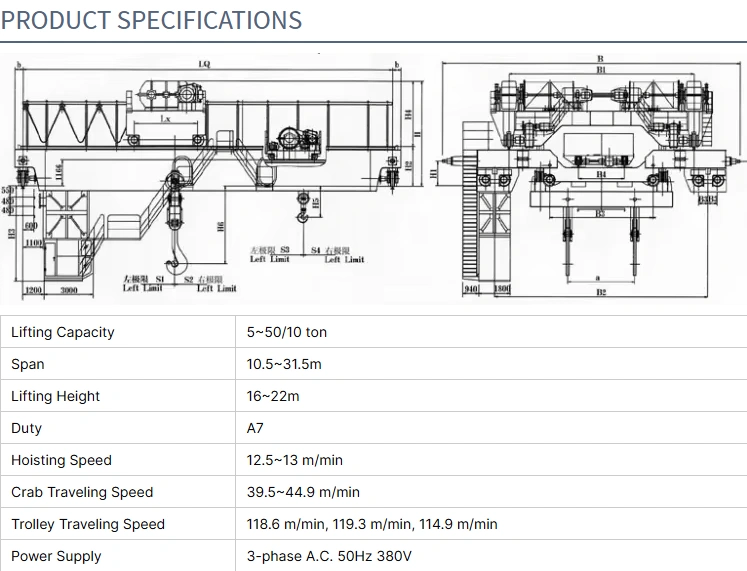

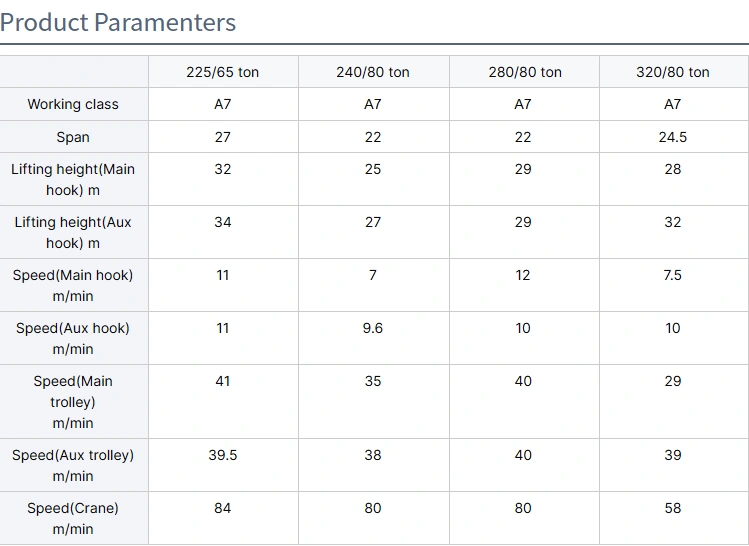

Product manual

Product manual